Tamis is Metal and Wood Surface Sanding and Grinding Machines Manufacturer.

To achieve perfect solutions on metal and wooden surfaces, we manufacturer multi-purpose abrasive machines / Band Sanding Machines / Band Grinding Machines / Polishing Machines / Double Armed Sanding Machines.

We collaborate with a team of experts for more than 33 years in order to create high-quality, high-performance, and long-lasting machines. With all of our expertise, we are aware of your priorities, needs, and requires. Because of this, every machine we make is a perfect fit for your requirements.

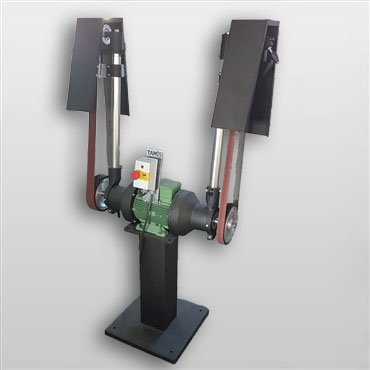

One-armed and double armed sanding machinery with discs and bands are provided in our extensive product line to grind, sand, and polish the surfaces of metal and wood. Discover them now!

Metal and Wood Surface Abrasive Machines Usage Areas

Machines produced by TAMIS provides multi-axis processing opportunity in sanding operations of irregularly shaped, curved and profiled elements, deburring and surface finishing operations.In sectors such as casting, aerospace, shock absorber, furniture, decoration manufacturing, sanding of metal and wooden surfaces, deburring, piping, metal cutting, metal cleaning and polishing, wood sanding, wood and knife sharpening, blacksmithing, repairing, etc. It takes its place in almost every manufacturing sector, from big factories to smaller.

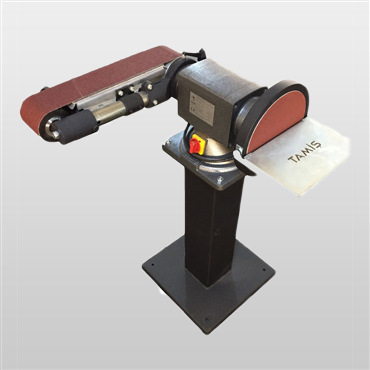

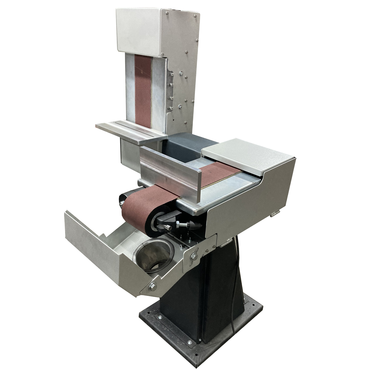

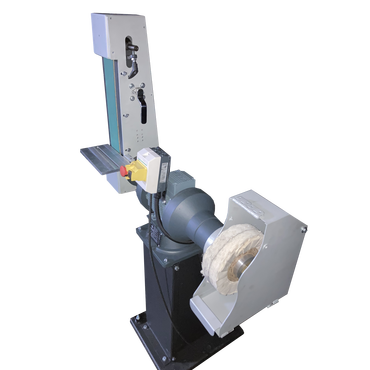

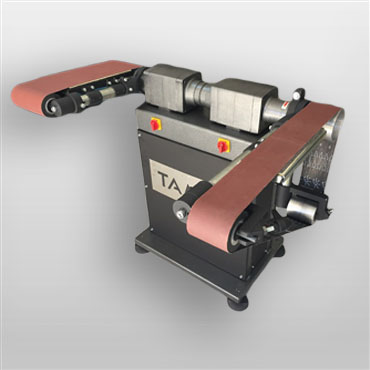

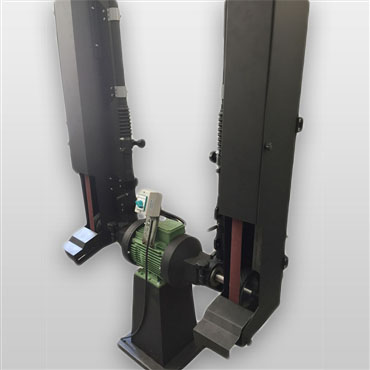

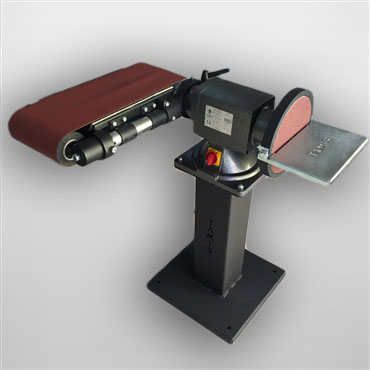

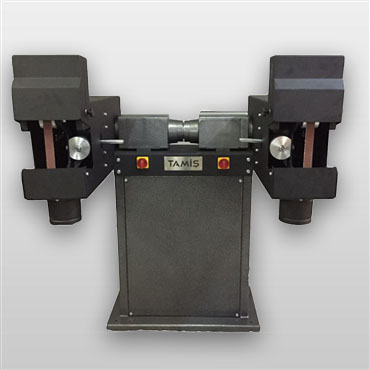

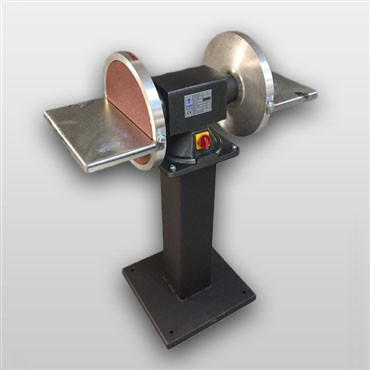

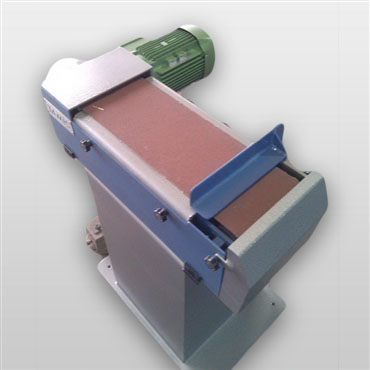

Band Sanding Machines/Grinding Machines/Polishing Machines

The machines made by Tamis can be modified at the request of the customer.By altering the band sizes, the customer's requests for requirements like an expanded work area, processing of big parts, and a long working life are satisfied.The right motor choice allows for the production of machines that can handle multiple users or that are appropriate for processes that require for excessive force and pressure.Along with the covering, these machines offer the user work safety.

Belt sander provides multi-axis processing opportunity in sanding, deburring and surface finishing of irregularly shaped, curved and profiled elements.With disc sander, the operations to be performed are carried out with the abrasive disc attached directly to the metal disc. Since the disc sander has a large circular surface, it provides a wide working area. For high precision squaring or straightening operations, it is suitable for corner breaking, deburring, or graduated machining (30, 45, 90) as desired thanks to the angle adjustable stop. Flat and vertical operations are easily performed on the disc sanding unit, which can be supported by a table.

In polishing machines, all kinds of materials are polished with different types and sizes of polishing felts applied with special liquid.

In particular, brushing, polishing and finishing of any metal material can be done in these polishing machines.

Discover our machines that fit your needs!